LRA Designer

Description

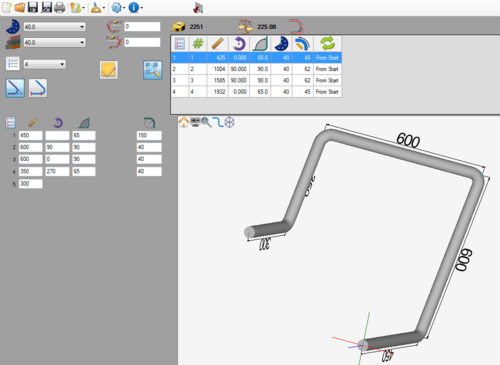

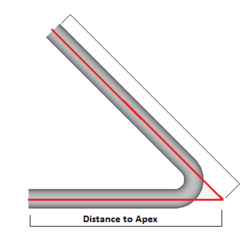

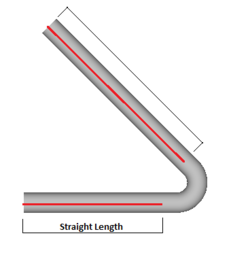

The LRA Designer allows parts to be created in full 3D. Parts are created by supplying length, rotations, and angle values for each bend. The straight length dimensions can be measured by the length of the straight sections of tube or by the distance from the apex of the bends. The option to give each bend a custom center-line radius value is also available.

A tutorial on how to create a part using this designer is available here: LRA Designer Tutorial

How To

Start Up

To access this designer, click the LRA designer button ![]() on the start up page. This will open a new, blank part design.

on the start up page. This will open a new, blank part design.

Part Design

Once a new LRA part design window has been opened, a new part can be created.

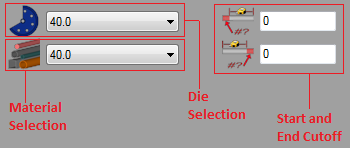

First, a die and material should be chosen. This can be done by clicking on the drop down menus next to the die and material icons in the top left corner of the screen.

If any cut-off is necessary, enter the amount needed into the start and end cut-off fields. The first/top field represents the cut-off at the start of the part and the second/bottom field represents the cut-off at the end of the part.

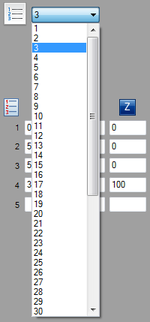

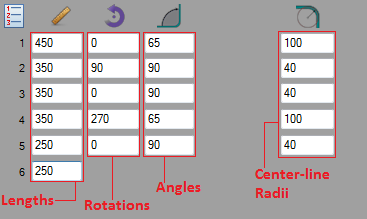

To start designing the part, enter values into the designer entry fields in the left panel. Each bend and the last straight length will have its own row. The first column below the ruler icon represents the straight lengths of tube. The second column below the arrow icon represents the rotations for each bend. Note: Leaving a rotation field blank will be the same as entering 0. The third column below the angle icon represents the angle of each bend. The fourth column off to the right represents the center-line radius for each bend. See image below.

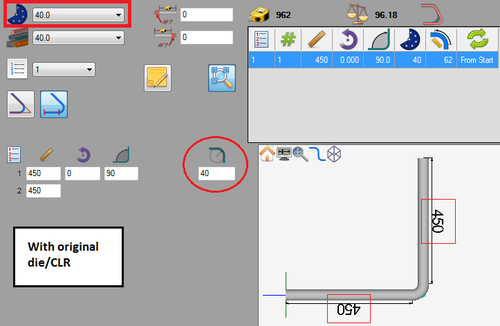

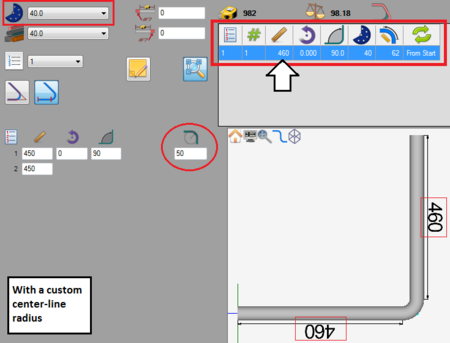

Each bend can be given a custom CLR. The purpose of the custom CLR function is to allow a part to be designed using the current die to replicate another part that is made with a different die/CLR(s). Giving a part a custom CLR will adjust (lengthen or shorten) the straight lengths of the part so that they would match up with a part with the given custom CLR. For example, if a part requires a 50mm CLR and the closest available CLR is a 40mm, adding a 50mm custom CLR will adjust the part lengths so the part shape will match up as close as possible to the intended part design while using the 40mm die. See images below.

Controls and Options

To change the way straight lengths of tube are measured, click on the distance to apex ![]() or length of straight

or length of straight ![]() buttons. See the image below for a basic explanation of these two options.

buttons. See the image below for a basic explanation of these two options.

Notes can be attached to the part design project using the note button ![]() . Notes are saved with the part and are included on the part's setup sheet.

. Notes are saved with the part and are included on the part's setup sheet.

The auto-zoom option can be turned on or off using the auto-zoom button (On) ![]() / (Off)

/ (Off) ![]() . When activated, auto-zoom will zoom in or out to accommodate the size of the part. For example, if a length is originally 200 and is changed to 2000, it may extend past the part display's extend. Auto-zoom will zoom out to make sure the whole part is visible.

. When activated, auto-zoom will zoom in or out to accommodate the size of the part. For example, if a length is originally 200 and is changed to 2000, it may extend past the part display's extend. Auto-zoom will zoom out to make sure the whole part is visible.