Difference between revisions of "Manufacture Checking Tutorial"

| Line 34: | Line 34: | ||

==='''Step 3'''=== | ==='''Step 3'''=== | ||

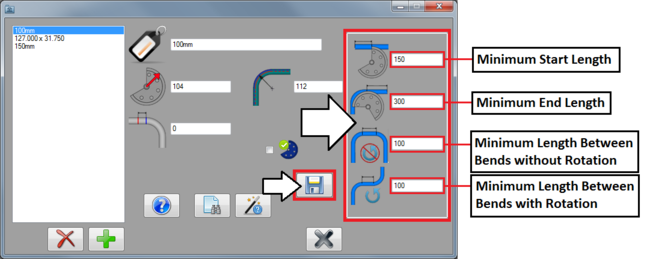

| − | The '''die limitations/minimum distances''' are on the far right side of the window, as shown in the image below. The shortest amount of material allowed before, after, and between bends with and without rotations can be specified. | + | The '''die limitations/minimum distances''' are on the far right side of the window, as shown in the image below. The shortest amount of straight material allowed before, after, and between bends with and without rotations can be specified. Keep in mind that these measurements only include the straight/unbent material before and between the bends. |

| Line 122: | Line 122: | ||

==='''Step 9'''=== | ==='''Step 9'''=== | ||

| − | '''Click on one of these warning icons'''. This will open a window that will contain a chart of each error in the part design. | + | '''Click on one of these warning icons'''. This will open a window that will contain a chart of each error in the part design. There should be '''three different problems listed here''': too short at start, too short at end, and too short between bends. In the last column, notice how the first two errors have auto-fixes available. |

| + | |||

| + | [[File:mancheck13.png|1000px]] | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | ==='''Step 10'''=== | ||

| + | [[File:mancheck14.png|right|350px]]The first issue with the part design is the length of the first straight/distance before the first bend. The problem description states that the part is '''84 units too short''' at the start. | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | ==='''Step 11'''=== | ||

| + | Auto fix, too short end | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | ==='''Step 12'''=== | ||

| + | too short between bends | ||

Revision as of 09:01, 22 July 2013

Contents

Introduction

This tutorial will demonstrate how to use the manufacture checking plug-in.

The manufacture checking plug-in uses the die limitations/minimum distances applied to the die in the die library. If any of the limitations are not met in the part design, a warning will be displayed in the results chart. Essentially, this plug-in ensures there is enough material is before, between, and after bends.

Tutorial

Note

Before starting the tutorial, a die must be created. This tutorial will be using the die that was created in the Die Library Tutorial. Please complete the Die Library tutorial before proceeding.

Step 1

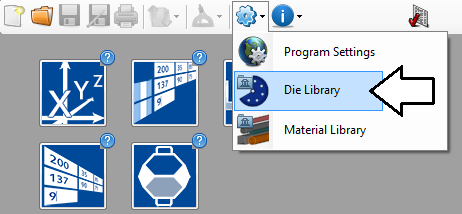

First, the die needs to be given some minimum distances. Go up to the main menu bar and click the Settings menu. Select the die library option from the drop down menu.

Step 2

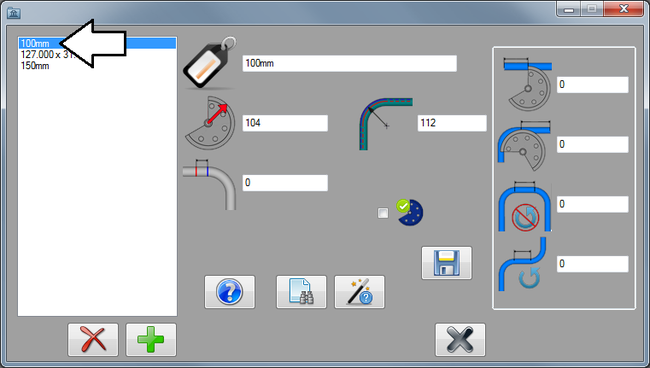

In the die library, click on the 100mm die in the die list to the left to select it.

Step 3

The die limitations/minimum distances are on the far right side of the window, as shown in the image below. The shortest amount of straight material allowed before, after, and between bends with and without rotations can be specified. Keep in mind that these measurements only include the straight/unbent material before and between the bends.

Enter 150 for the minimum start length, 300 for the minimum end length, 100 for the distance between bends without rotation, and 100 for the distance between bends with rotation.

Once these are all properly entered, click the save button.

Step 4

Next, a part will be created using the template designer. The part will be made with incorrect dimensions on purpose to allow the manufacture checking plug-in to detect problems in the part design.

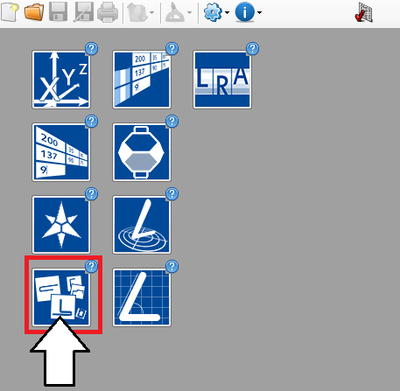

First, click the template designer button on the start up page.

Next, a part template will be chosen from the template selection menu. First, click the show all button ![]() and then click the medium sized tile button.

and then click the medium sized tile button. ![]()

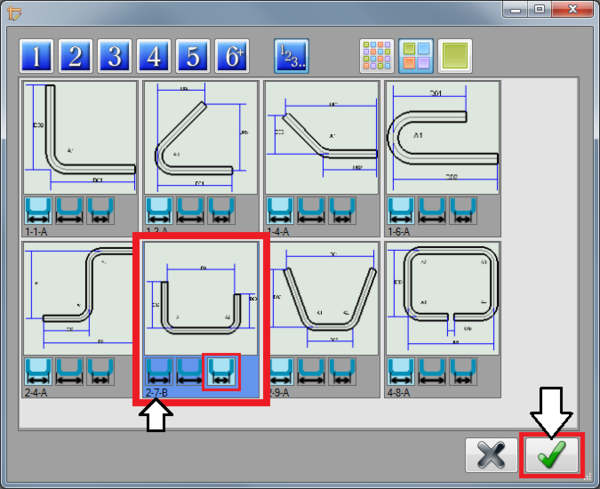

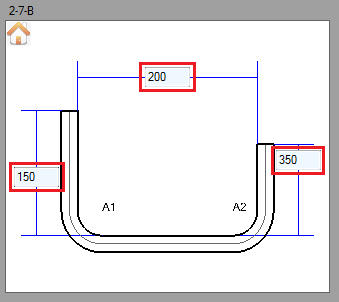

Click on the template shown below and choose inside dimensions by clicking the inside dimensions icon right below the template. Before proceeding, make sure the bottom left corner of the template says 2-7-B.

Click the green check button in the bottom right corner to finalize the template selection.

Step 5

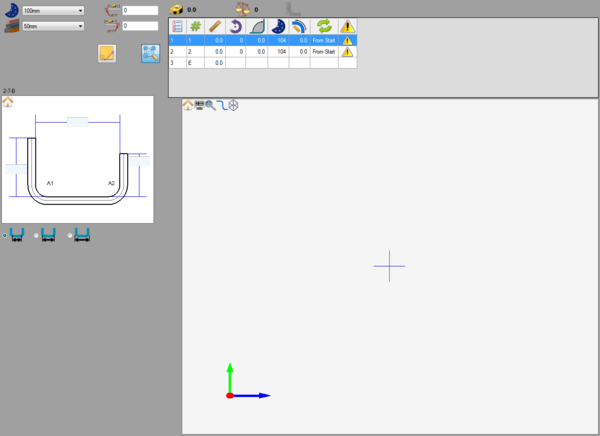

A new template part design window will open.

Step 6

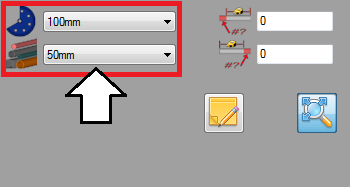

Now, select the die and material. The die and material menus are located in the upper left corner.

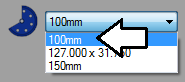

Choose a die by clicking the drop down menu next to the die icon. Select the 100mm die from the list, as shown in the image below. This is the die that the die limitations were given to in the first steps of this tutorial.

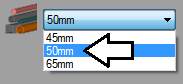

Choose a material by clicking the drop down menu next to the material icon. Select the 50mm material from the list, as shown in the image below. (Note: This material was made in the Material Library Tutorial. If this material is not shown in the material selection menu, either complete the material library tutorial or just select another material that is available.)

Step 7

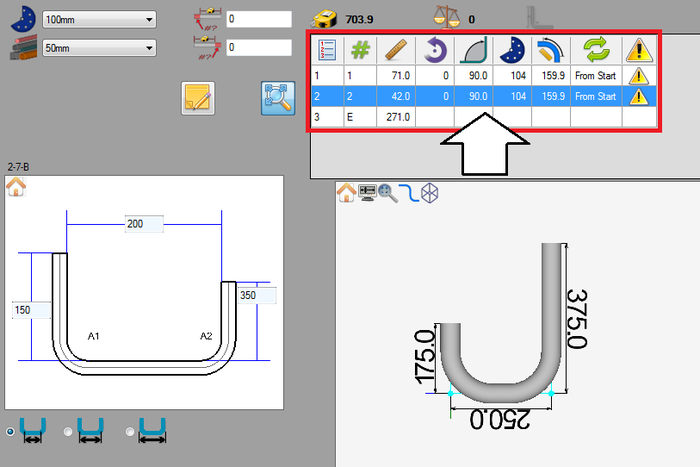

Now, the part will be designed. Enter the coordinates as shown below.

Enter 145 into the far left field, enter 99 into the upper middle field, and enter 250 into the right field. See image below.

Step 8

Next, look at the results table at the top of the window. In the last column, each row will have a warning icon.

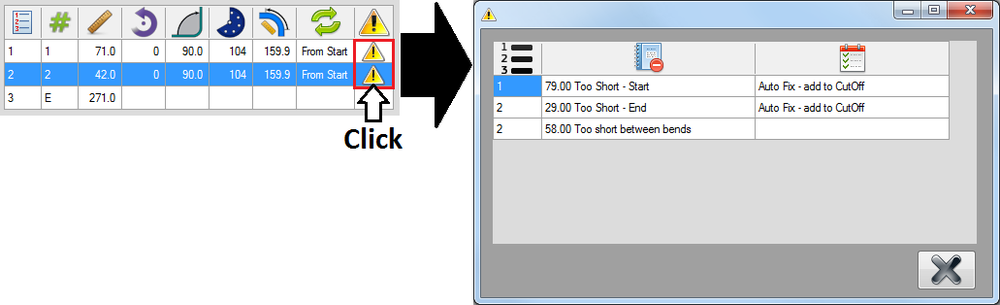

Step 9

Click on one of these warning icons. This will open a window that will contain a chart of each error in the part design. There should be three different problems listed here: too short at start, too short at end, and too short between bends. In the last column, notice how the first two errors have auto-fixes available.

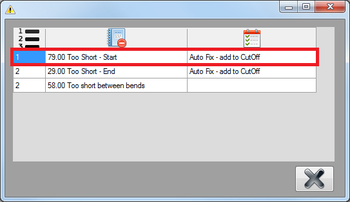

Step 10

The first issue with the part design is the length of the first straight/distance before the first bend. The problem description states that the part is 84 units too short at the start.

Step 11

Auto fix, too short end

Step 12

too short between bends