Linear Dynamic Designer Tutorial

Contents

Introduction

This tutorial will step through the process of designing a part (Shown to the right) in the linear dynamic part designer interface.

While designing a part in the linear dynamic designer, the die and material are chosen then the part is designed by dragging/pulling the part to size using the part designer tools and/or entering values into the entry fields.

Note: This tutorial will use millimeters as the measurement units.

Tutorial

Step 1

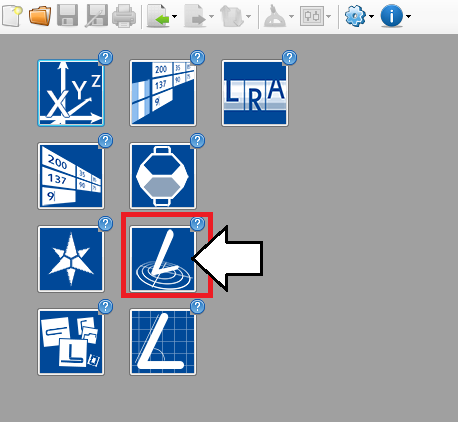

First, a new linear dynamic design needs to be started. On the start up page, click the linear dynamic designer button.

Note: Depending on the version of software currently in use, fewer designer buttons may be included on the start up page.

Step 2

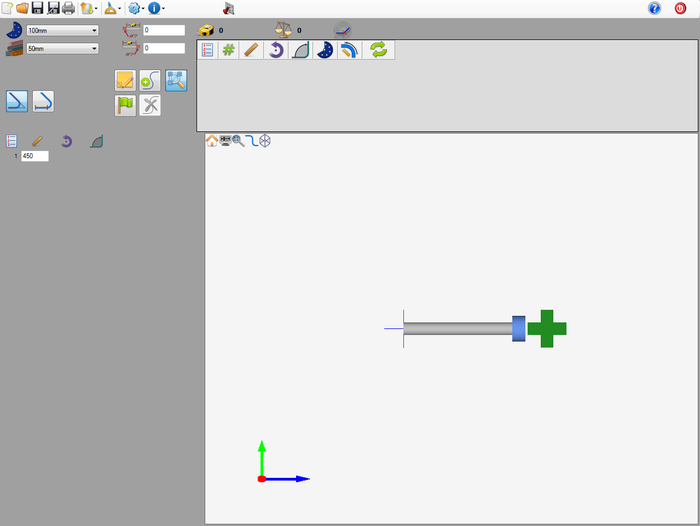

Now a new linear dynamic part designer window will open. This is where the part will be designed.

Step 3

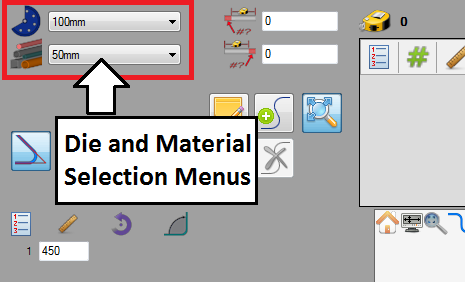

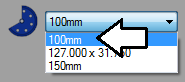

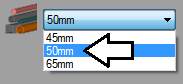

First of all, the die and material need to to be chosen. The die and material menus are located in the upper left corner of the designer window.

Choose a die by clicking the drop down menu next to the die icon. Select the 100mm die from the list, as shown in the image below. (Note: This die was made in the Die Library Tutorial. If this die is not shown in the die selection menu, please complete the die library tutorial before proceeding.)

Choose a material by clicking the drop down menu next to the material icon. Select the 50mm material from the list, as shown in the image below. (Note: This material was made in the Material Library Tutorial. If this material is not shown in the material selection menu, please complete the material library tutorial before proceeding.)

Step 4

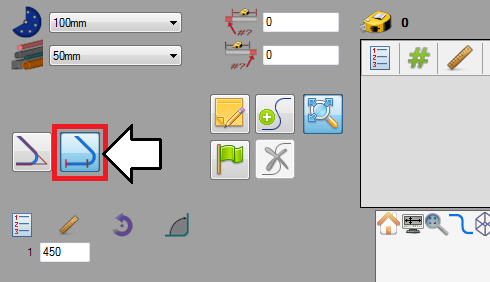

In the linear dynamic designer, the option to change the dimensions type/location is available. Dimensions can be measured up to the apex of the bend or just the straight lengths of tube. For more information see the dimension types section on the linear dynamic designer quick start page.

In this tutorial, the length of straight dimension type will be used. Click the length of straight button as shown below.

Step 5

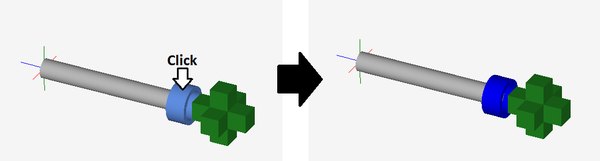

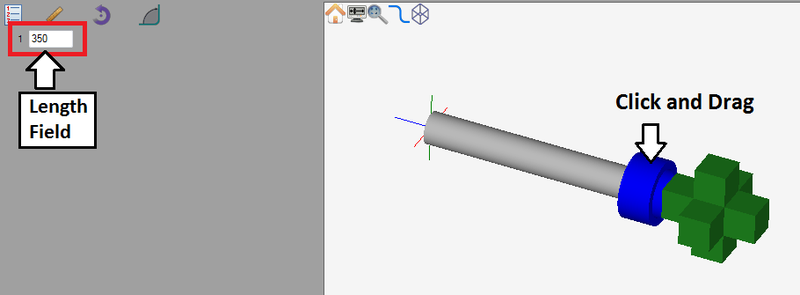

Now, the first length of the part will be designed. In the graphical display, a short piece of tube is already drawn out when the designer is opened. At the end of this length of tube, there will be a blue ring that will be used to adjust the length by pulling the tube to size.

Before a design tool is used, it needs to be selected first. Click on the blue ring to select it. Once selected, it will be a darker blue as shown below. Do this before adjusting any lengths on a part.

Click and drag the length to about 350 mm. To tell how long the length is, watch the length field on the left.

Tip: While clicking and dragging the part to size is convenient, getting exact measurements can be tricky. Any of these other methods can be used to adjust the part design:

1. Click on the appropriate design tool/ring and directly enter the value (length, rotation, or angle) using the keyboard.

Or...

2. Enter the exact length, rotation, or angle into the entry fields on the left.

Step 6

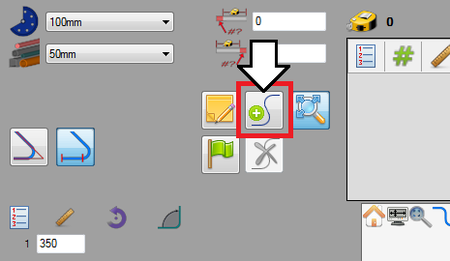

Now the first bend will be added to the part. First, click the add bend button.The add bend button is located near the upper left corner, as shown in the image to the right.

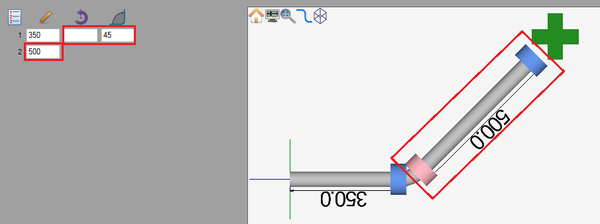

After a bend is added, another length will automatically be added to the part in the graphical display and a rotation, angle, and a new length field will appear in the entry fields area.

There is no need for any rotation before this bend, so leave the rotation field blank.

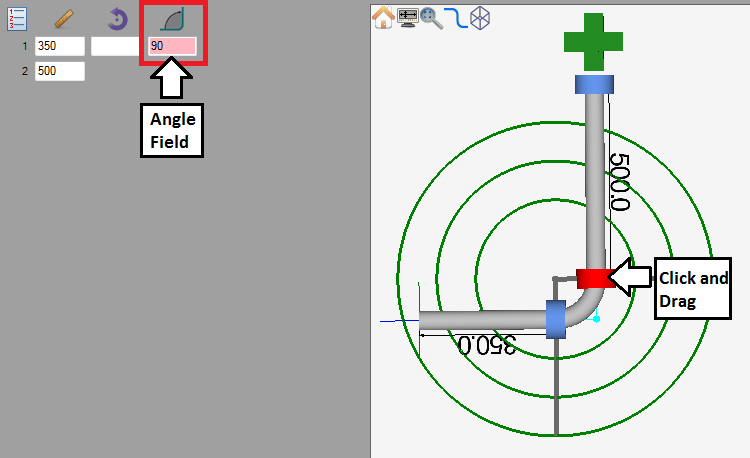

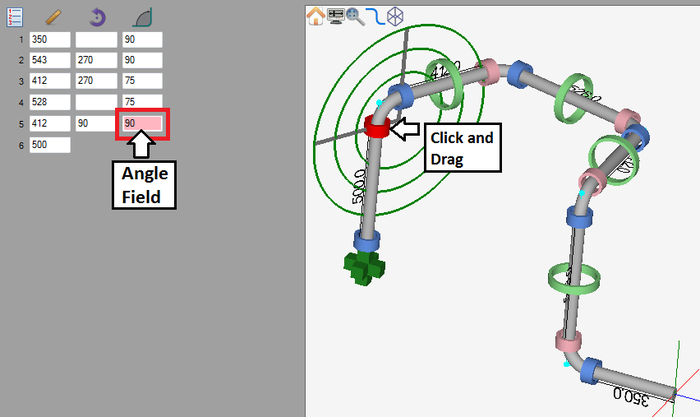

First, the angle of this bend will be adjusted. Make sure to select the correct angle ring before adjusting the angle of the bend. Click on the pink angle ring to select it. Once it is selected, it will be highlighted in red as shown below.

Click and drag the pink ring to approximately 90°. Keep track of the angle by checking the value shown in the angle field. (Alternate methods: Type the value (90) into the angle field or click the design tool/pink angle ring and directly type in the angle.)

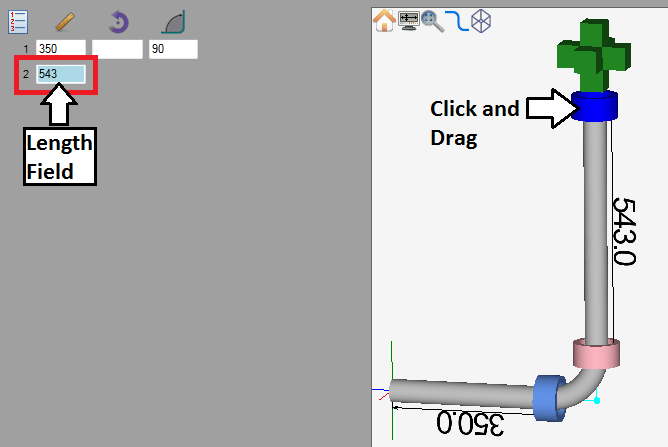

Next, the length after the bend will be adjusted. Click and drag the blue ring at the end of the part to roughly 543 mm. (Alternate methods: Type the length (543) into the length field or click the design tool/blue ring and directly type in the length.)

Step 7

In this step, the second bend will be added to the part. Click the add bend button. ![]()

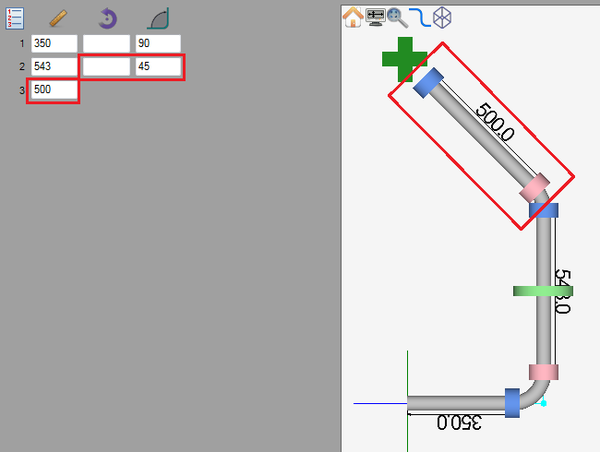

After a bend is added, another length will automatically be added to the part in the graphical display and a new rotation, angle, and length field will appear in the entry fields area, as shown in the image below.

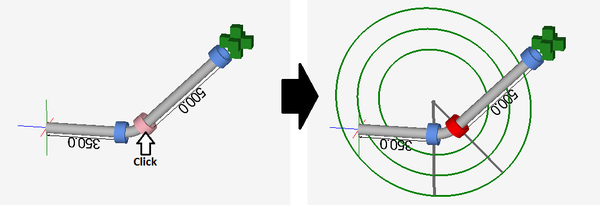

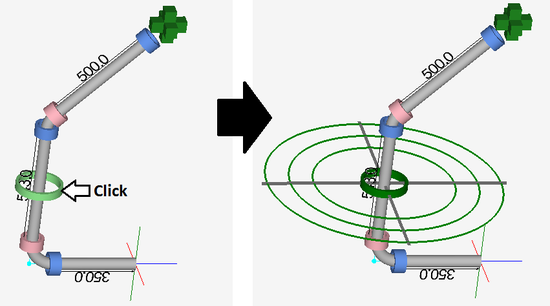

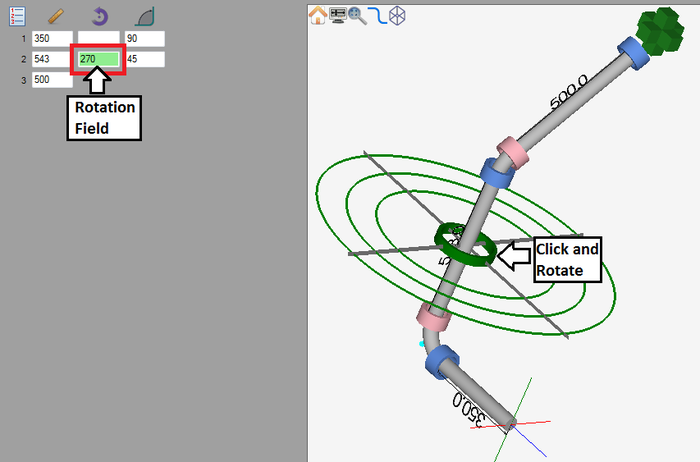

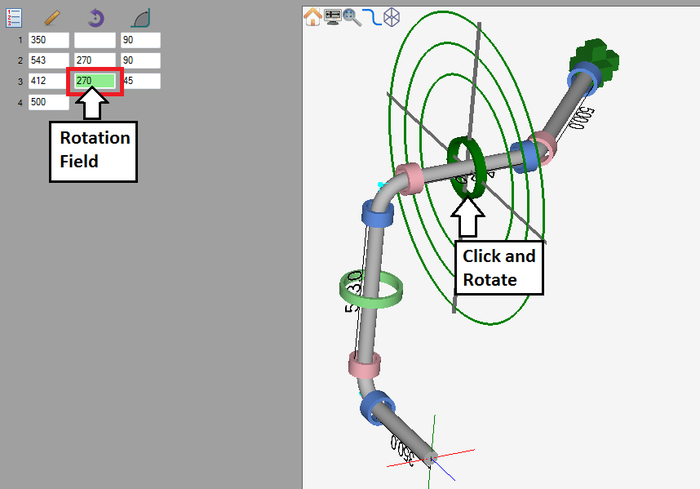

First, adjust the rotation. Be sure to select the green rotation ring before adjusting the rotation. Click on the green ring to select it. Once selected, the ring will be a darker green as shown below.

Click and rotate the light green rotation ring until the rotation field reads 270° (Alternate methods: Type the rotation value (270) into the rotation field or click the design tool/green ring and directly type in the rotation.)

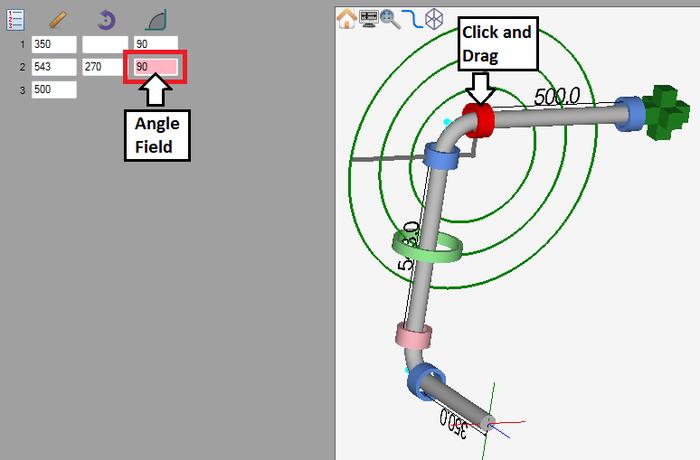

Next, adjust the angle. Click and drag the pink ring until the angle measures about 90°. (Alternate methods: Type the angle value (90) into the angle field or click the design tool/pink ring and directly type in the angle.)

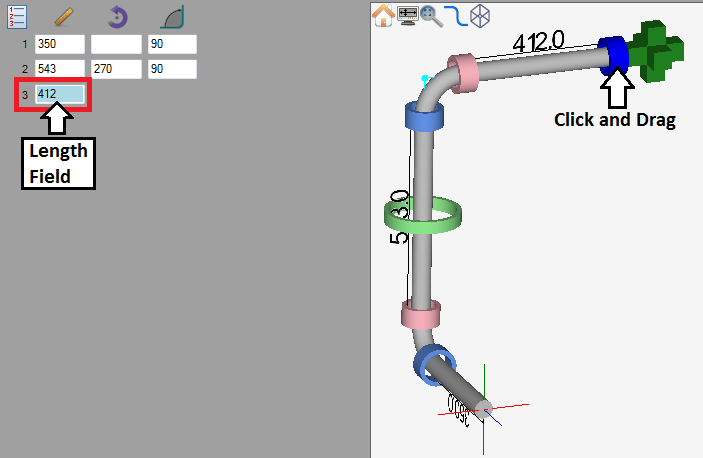

Lastly, adjust the length. Click and drag the last blue ring until the length is around 412 mm. (Alternate methods: Type the length value (412) into the length field or click the design tool/blue ring and directly type in the length.)

Step 8

Now the third bend will be created. Click the add bend button. ![]()

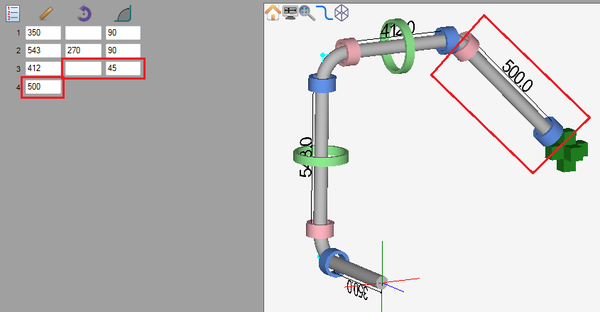

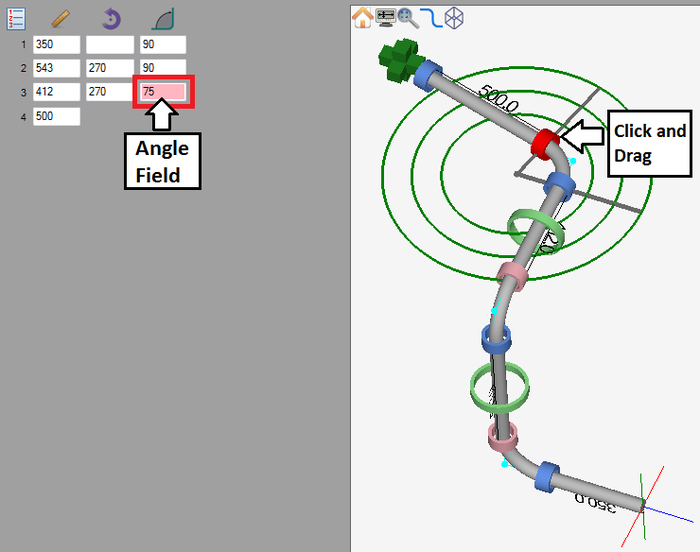

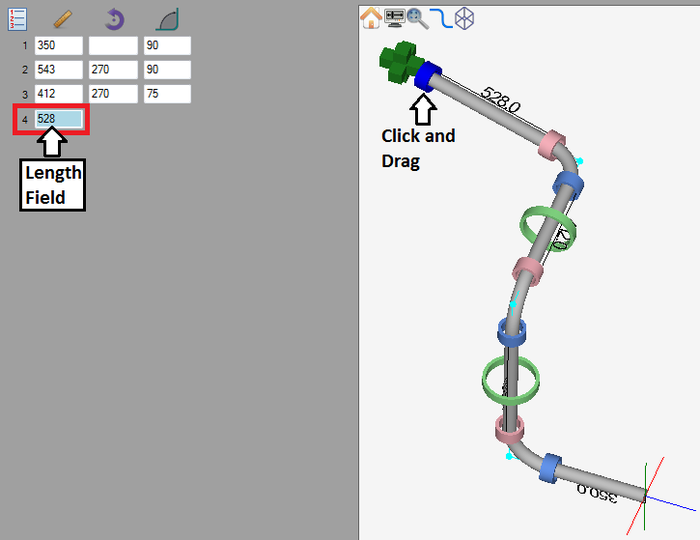

After a bend is added, another length will automatically be added to the part in the graphical display and a new rotation, angle, and length field will appear in the entry fields area, as shown in the image below.

First, adjust the rotation. Click and rotate the green ring around until the rotation field reads 270°. (Alternate methods: Type the rotation value (270) into the rotation field or click the design tool/green ring and directly type in the rotation.)

Next, adjust the angle. Click and drag the pink ring until the angle is about 75°. (Alternate methods: Type the angle value (75) into the angle field or click the design tool/pink ring and directly type in the angle.)

Then adjust the length. Click and drag the blue ring until the length measures around 528 mm. (Alternate methods: Type the length value (528) into the length field or click the design tool/blue ring and directly type in the length.)

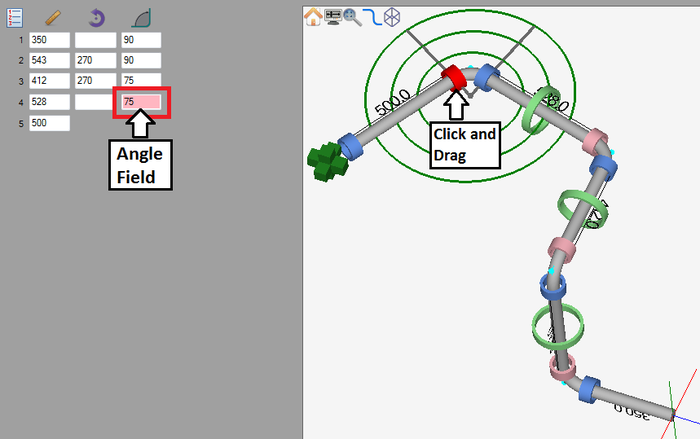

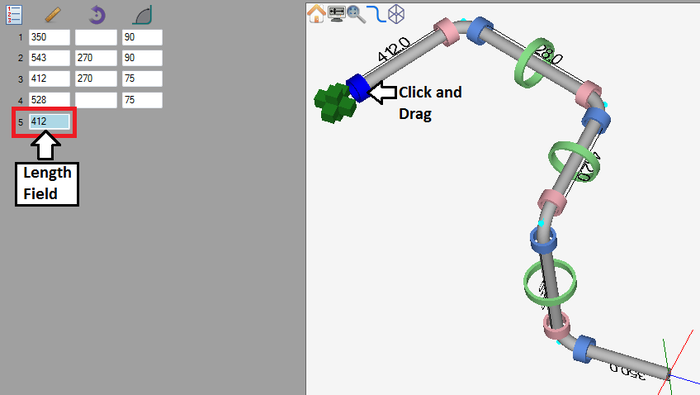

Step 9

In this step, the fourth bend will be created. Click the add bend button. ![]()

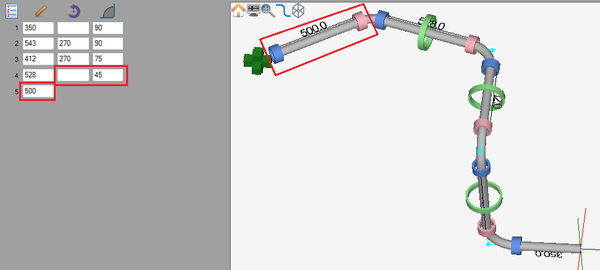

After a bend is added, another length will automatically be added to the part in the graphical display and a new rotation, angle, and length field will appear in the entry fields area, as shown in the image below.

There is no need to adjust the rotation, so leave the rotation field blank. First, adjust the angle. Click and drag the pink ring until the angle is about 75°. (Alternate methods: Type the angle value (75) into the angle field or click the design tool/pink ring and directly type in the angle.)

Now, adjust the length. Click and drag the blue ring until the length measures about 412 mm. (Alternate methods: Type the length value (412) into the length field or click the design tool/blue ring and directly type in the length.)

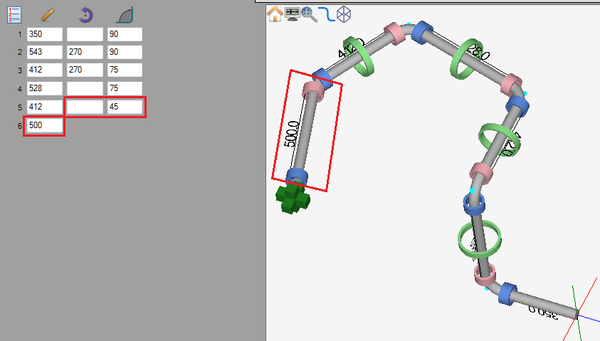

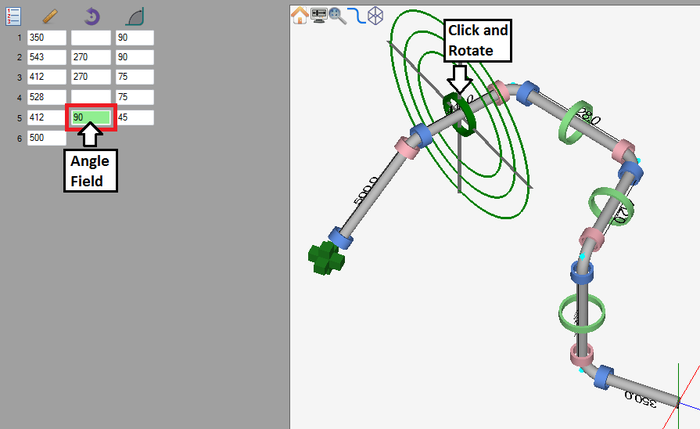

Step 10

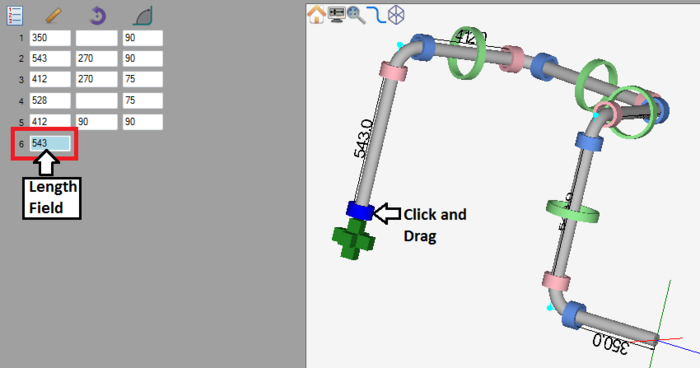

In this step, the fifth and final bend will be created. Click the add bend button. ![]()

After a bend is added, another length will automatically be added to the part in the graphical display and a new rotation, angle, and length field will appear in the entry fields area, as shown in the image below.

First, adjust the rotation. Click and rotate the green ring around until the rotation field reads 90°. (Alternate methods: Type the rotation value (90°) into the rotation field or click the design tool/green ring and directly type in the rotation.)

Next, adjust the angle. Click and drag the pink ring until the angle measures around 90°. (Alternate methods: Type the angle value (90) into the angle field or click the design tool/pink ring and directly type in the angle.)

Finally, adjust the length of the last straight section. Click and drag the blue ring until the length is about 543 mm. (Alternate methods: Type the length value (543) into the length field or click the design tool/blue ring and directly type in the length.)

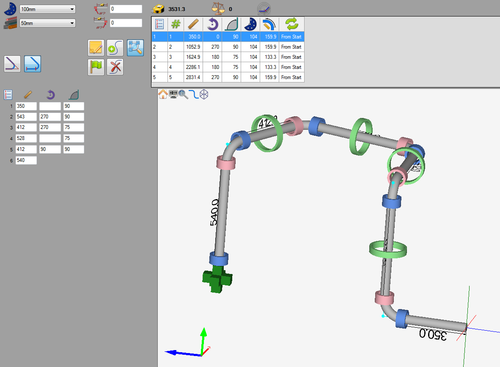

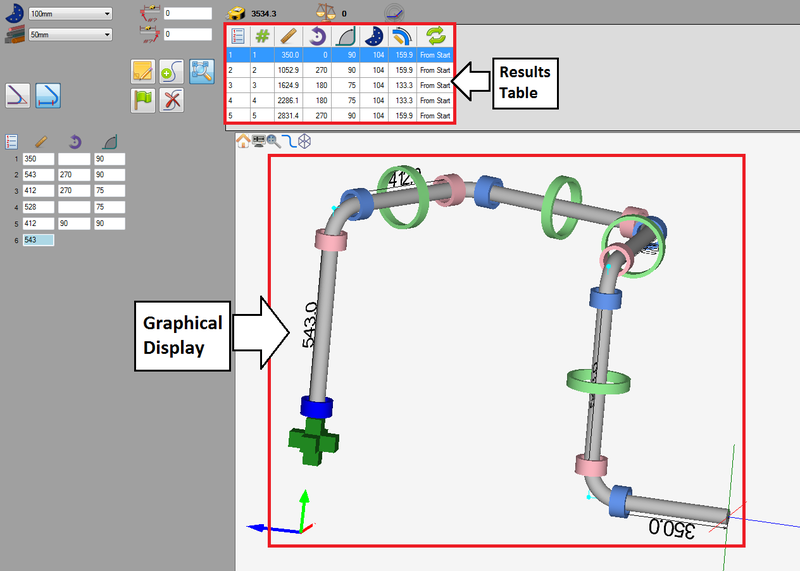

Step 11

A 3D model of the part can be viewed in the graphical display. The part's bend information will also be generated in the results table at the top of the window. See the image below.

Depending on the options chosen in the results/output format and results/output settings tabs in the program settings menu, the results table may look slightly different.

Step 12

The part is now complete!

The part design file can be saved by going up to the main tool bar and clicking the save option. ![]()

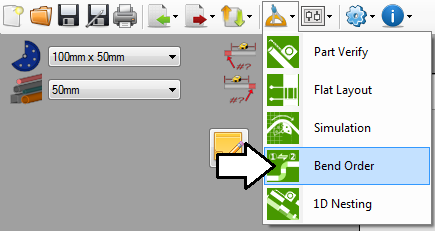

The bend order can also be adjusted in the bend order menu.

The part setup sheet can also be printed by clicking the print option on the main tool bar. ![]()